This water-based graphite lubricant was developed to provide:

– Higher productivity

– Reduced tool wear

– Reduced scrap rate

– Reduction of forging loads

– Resistance to sticking – release properties

– Cooling and improved die life

– Assistance to metal flow

– Reduced friction and reduced rejects

– Reduced scale- Die and forging

– Consideration for safety and environmental protection.

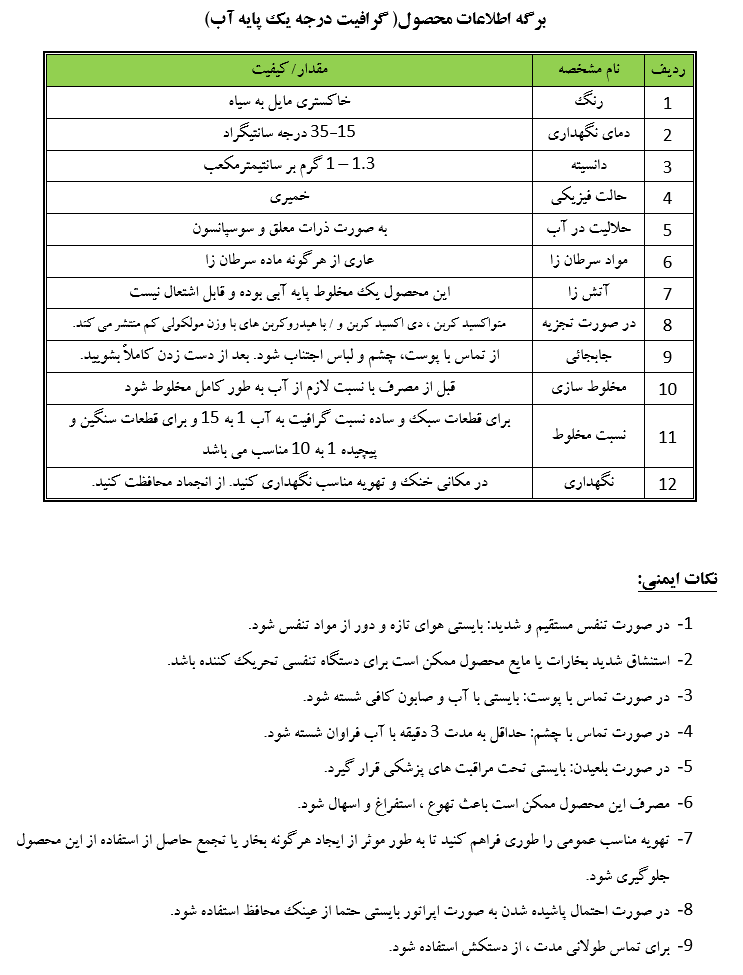

Data Sheet

Flowable dispersion of high purity fine particle size graphite in a mineral containing carrier fluid. Suitable for a wide range of applications. Can be applied by spraying. Water-based graphite lubricants contain a binder that holds the graphite particles to all surfaces of the die and reduces the amount of overspray. A safe, non-toxic, lamellar solid offering excellent friction reducing properties. Clean working environment and very economic because of using water as a main carrier. Non-graphite forging lubricants tend to leave a translucent or transparent film. This makes it difficult for the operator to visually tell whether the die has been properly lubricated. A dark-gray water-based graphite lubricant film is much easier to observe.

Methods of Application

Water-based graphite forging lubricants are designed to be diluted with potable water and are odor-free in most cases.

Although easily mixed, water-based graphite lubricants require agitation to ensure a homogeneous mixture throughout the ready-for-use product when diluted.

If spray application and dilution equipment is not maintained properly, water-based graphite forging lubricant can cause plugging problems in lines and spray nozzles. This may result in downtime to clean the systems or, if not caught in time, produce rejected parts or premature die wear due to poor die lubrication.

For most effective use, die temperature should be approaching 150°C minimum with the ideal range being 200-250°C. It will provide minimum spray time and quick drying time of coating.

Die heating should be maintained during production stoppages.

It is always advisable to continually agitate the mixed material. Slow, mechanical stirring is by far the most effective method.

This product is used at lubricant/water dilutions of 1:10, or 10% concentration for complicated parts to 1:15 (lubricant/water), or 6.5% concentration for simple parts. This produces a low ready-for-use lubricant cost. Lower dilution ratios also lead to higher freight, handling and storage costs.